Best Times for Wrought Iron Repairs

Wrought iron repairs are most effectively performed during mild weather conditions. Optimal times include spring and early fall when temperatures are moderate and humidity levels are lower. These conditions help ensure proper curing and adhesion of repair materials, reducing the risk of future corrosion.

Spring offers ideal weather for wrought iron maintenance, with warmer temperatures and less rain, facilitating effective repairs and preventing rust formation.

Early fall provides cooler, dry conditions that are suitable for repairing and restoring wrought iron before winter weather sets in.

Extreme cold or heat can hinder repair processes, cause materials to cure improperly, and increase the risk of cracking or corrosion.

Spring weather allows for optimal conditions for wrought iron restoration projects.

Fall provides suitable dry and moderate temperatures for repairs.

Moderate weather ensures proper curing and longevity of wrought iron repairs.

Ways to make Wrought Iron Repairs work in tight or awkward layouts.

Popular materials for Wrought Iron Repairs and why they hold up over time.

Simple add-ons that improve Wrought Iron Repairs without blowing the budget.

Wrought iron is a durable material commonly used for gates, fences, and decorative fixtures. Over time, exposure to moisture and environmental elements can lead to rust, corrosion, and structural deterioration. Proper repair and maintenance are essential to preserve its aesthetic appeal and structural integrity. Statistics indicate that timely repairs can extend the lifespan of wrought iron structures by decades, reducing long-term costs and preserving property value.

Effective rust removal is critical for successful wrought iron repairs.

Proper cleaning and preparation ensure optimal adhesion of repair materials.

Protective coatings help prevent future corrosion and enhance appearance.

Completed repairs restore strength and aesthetic appeal to wrought iron fixtures.

High-end options that actually feel worth it for Wrought Iron Repairs.

Finishes and colors that play nicely with Wrought Iron Repairs.

Little measurements that prevent headaches on Wrought Iron Repairs day.

A 60-second routine that keeps Wrought Iron Repairs looking new.

A frequent mistake in Wrought Iron Repairs and how to dodge it.

Small tweaks to make Wrought Iron Repairs safer and easier to use.

Lower-waste or water-saving choices for Wrought Iron Repairs.

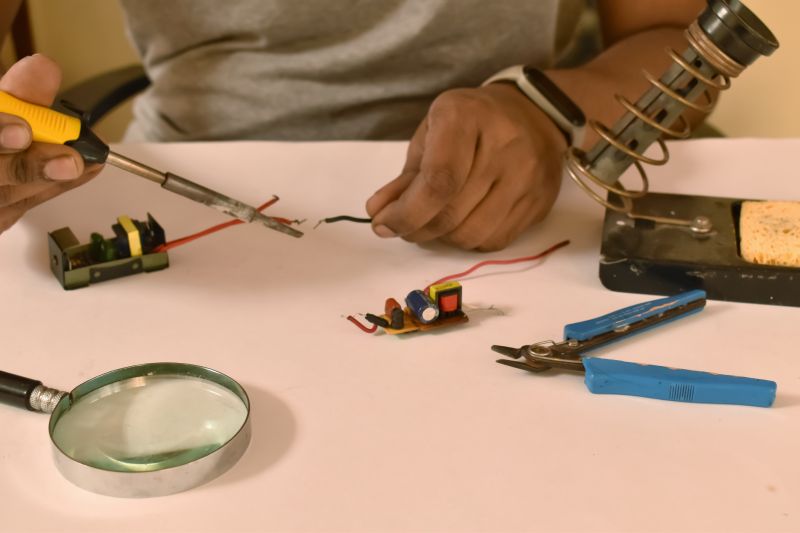

The short, realistic tool list for quality Wrought Iron Repairs.

| Season | Ideal Conditions |

|---|---|

| Spring | Moderate temperatures, low humidity, minimal rain |

| Early Fall | Dry weather, cool temperatures, low humidity |

| Late Fall | Cooler temperatures, preparation for winter |

| Winter | Not recommended due to cold and moisture risks |

| Summer | High temperatures and humidity, risk of rapid drying or cracking |

Choosing the right time for wrought iron repairs enhances durability and appearance. Proper timing ensures materials cure correctly and reduces the risk of future damage. Regular maintenance during optimal seasons can significantly prolong the lifespan of wrought iron fixtures, preventing costly replacements.

Restoration projects benefit from favorable weather conditions.

Timing repairs appropriately helps prevent rust and corrosion.

Scheduling repairs during suitable seasons maximizes effectiveness.

Rough timing from prep to clean-up for Wrought Iron Repairs.

Quick checks and paperwork to keep after Wrought Iron Repairs.

Examples that show the impact a good Wrought Iron Repairs can make.

For those interested in wrought iron repairs, filling out the contact form can facilitate scheduling and consultation. Proper timing and maintenance ensure wrought iron fixtures remain functional and visually appealing for years to come.